Next Generation Warehouse Automation Solution

Get to Know the Next Generation Warehouse Automation Solution

Warehouse automation has taken a leap forward into the future with the Omni-Mole® Automated Storage & Retrieval System (AS/RS). It is a next-generation solution that simplifies, streamlines and optimises high-density pallet storage with characteristics like:

- Flexibility

- Scalability

- Efficiency

What is the Omni-Mole®?

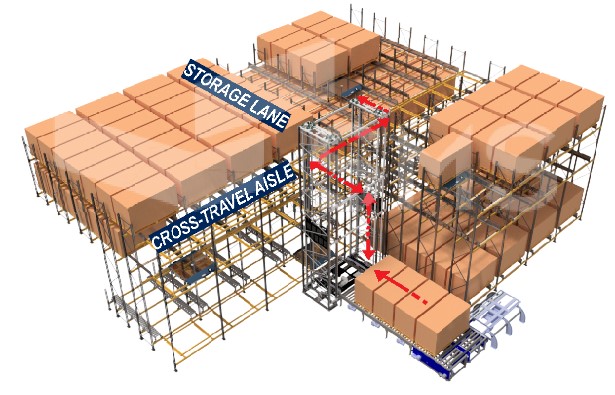

It is a warehouse bi-directional, deep-lane palletised load automation system. With the lift and run operation, it provides for maximum flexibility in the load throughput. The system can be adapted to fit the warehouse facility and capacity requirements of the client.

What are the main features that set the Omni-Mole® apart from other warehouse automation systems?

The cart-based palletised storage system has several more features than just flexibility, scalability and efficiency. These include:

- Streamlined technology for easier and faster operation.

- Automated material handling.

- Perfect for higher density in storage.

- With only a minimum of travel aisles required, space can be used to the fullest.

- The throughput capacity can be adjusted increased with more system resources to meet higher volume demand.

- Exceptional reliability.

- Easy maintenance.

- High parallel operation capacity.

- Perpetual pallet count, which is automated for best accuracy and no downtime.

- High-density capacity – far superior to the AS /RS crane systems.

Highly efficient operation

Storage Management Systems (SMS) is committed to the development and supply of automation solutions that are easy to maintain, straightforward in operation and scalable to fit the client’s operational requirements. The Omni-Mole® is the result of this commitment. The system is the progenitor of the Pallet Mole® platform. Instead of a one-dimensional plane as has been possible with the Pallet Mole®, the Omni-Mole® has a shuttle movement on a two-dimensional plane.

Pallets are vertically moved to the correct height with the vertical transfer unit (VTU). Using this technology, pallets can be moved to any location in the high-density storage system. The automated guided vehicles (AGV / AMR) and conveyors compliments additional automation on the in- & outbound of the system.

Sophisticated software for more control

Further contributing to warehouse automation, is the software, namely the Warehouse Execution System (WES), which consists of an inventory management system, a control system and a resource management system.

The perfect warehouse automation applications

The system is well-suited for the rack clad facility where racking makes up an integral part of the structure. In this sense, the racking supports the building envelope together with the stored products. It is also well-suited for picking tunnels located at surface level, making it possible for order pick using a sortation system, conveyor or trolley system.

Final thoughts

High-density storage and retrieval provide for space and labour savings. The revolutionary Omni-Mole® system that consists of the Omni-Mole®, the vertical transfer unit and WES software , is the next generation in storage facility automation. With 100% higher capacity than the crane systems, it is one solution that improves productivity, makes the best use of available space.

Make the best use of your warehouse space. Get in touch for more information about the Omni-Mole® as a next-generation storage facility automation solution.

Sources: